Plastics, Rubber & Polymers

Are surprisingly poor at keeping water out

Click

on the image to download a print quality scan

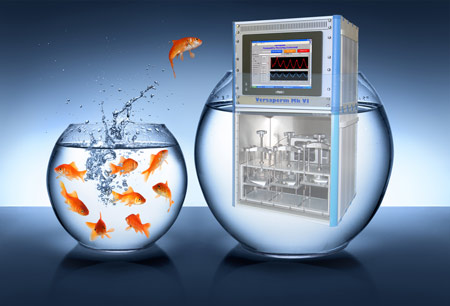

Countless plastic, rubber and polymer products are very poor as gas and water vapour barriers, even though they may be excellent barriers for liquids. This affects their physical characteristics, sometimes dramatically, including strength, handling and the way they print and perform in general.

Thanks to Versaperm, measuring this effect (permeability) has become fast and easy, not just for water vapour, but also for most other gases including hydrocarbons, oxygen, CO2 and nitrogen. The need to measure this is extremely widespread as it affects the performance of almost every plastic or rubber component.

Quantifying the permeability of plastics, rubber and polymer films, laminates and products is the key to reducing many widespread problems – such as medications that lose potency, electronics that fails and food that goes stale too quickly.

Versaperm's permeability equipment gives accuracies that are typically measured in the parts per million range, (parts per billion with some gases). The system is ideal for use on most plastics or rubber materials, containers, films coatings and components.

As well as manufacturing the instruments, Versaperm offers a permeability laboratory service for companies that need to test samples on an irregular basis.

ENDS

Please send

any sales enquiries to Christopher Roberts, Versaperm Limited ,

10 Rawcliffe House, Howarth Road, Maidenhead, Berkshire, SL6 1AP, UK, Tel: +44 (0) 1628 777668,

e.mail info@versaperm.co.uk

Web http://www.versaperm.co.uk

For further

Press Information please contact Gerry Palmer @ the Palmer & Rose

Partnership. Tel +44 (0) 1494 637499, e.mail gerry@palmer-rose.co.uk.

|